Heavy Duty Line Vac™ – Our most powerful Line Vac moves high volumes of material and resists wear!

What Is The Heavy Duty Line Vac?

The Heavy Duty Line Vac is a powerful conveyor. The appearance is similar to the standard Line Vac but performance has been boosted dramatically. It has been engineered to convey materials over longer vertical and horizontal distances. The hardened alloy construction helps prevent premature wear that could occur with ordinary aluminum or stainless steel Line Vacs.

Heavy Duty Line Vacs are available in five sizes: 3/4″ (19mm), 1″ (25mm), 1 1/4″ (32mm),

1 1/2″ (38mm) and 2″ (51mm).

The hardened alloy construction resists wear

and conveys over longer distances.

Why The Heavy Duty Line Vac?

Many applications require the materials be transported over longer distance. The Heavy Duty Line Vac can move more material over longer lengths. They have been designed for rugged, industrial applications.

The table below gives a quick comparison of our Light Duty Line Vac, standard Line Vac, and the Heavy Duty Line Vac models. For comparison, the test shows the 2″ (51mm) model of each style conveying the same material over various lengths. Heavy Duty Line Vac conveys more material in less time.

| Rock Salt Conveying Rate Comparison | ||

|---|---|---|

| 100 Feet (30,5 m) | 200 Feet (61 m) | |

| Model 130200 2″ (5 1mm) Light Duty Line Vac | 166 lbs/hr. (75,3 kg/Std.) | N/A |

| Model 6084 2″ (51 mm) Line Vac | 334 lbs/hr. (151,5 kg/Std.) | 85 lbs/hr. (38,6 kg/Std.) |

| Model 150200 2″ (51mm) Heavy Duty Line Vac | 524 lbs/hr. (237,7 kg/Std.) | 200 lbs/hr. (90,7 kg/Std.) |

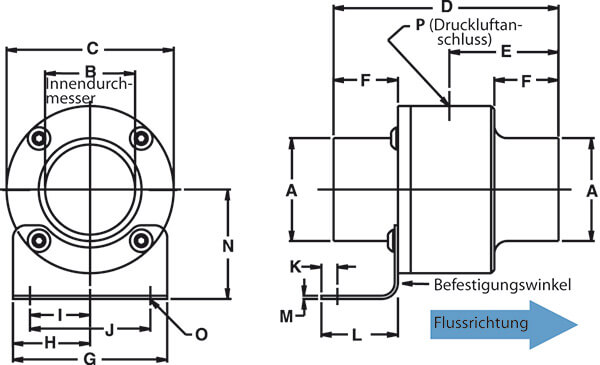

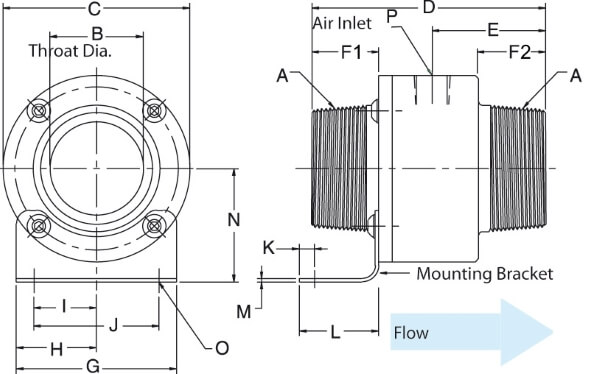

Heavy Duty Threaded Line Vac

EXAIR’s new Heavy Duty Threaded Line Vac air operated conveyors convert ordinary pipe into a powerful conveying system for parts, scrap, trim and other bulk materials. The engineered Heavy Duty Threaded Line Vac attaches easily to ordinary NPT pipe and fittings available from any home center, hardware store or plumbers supply. With its hardened alloy construction, the Threaded Heavy Duty Line Vac withstands premature wear which could occur with aluminum and stainless steel.