Temperatures: Internal mix atomizing nozzles are designed up to 204°C.

Please click here (PDF) for droplet size and spray pattern.

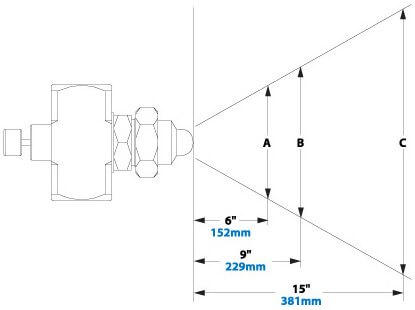

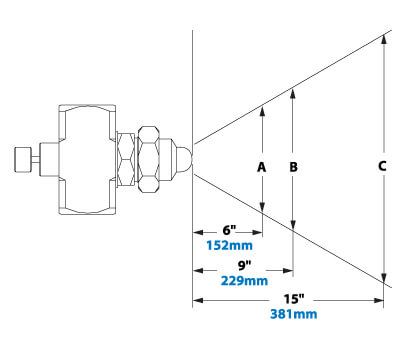

| Spray Pattern |

| Model |

Pressure |

Width |

Max. Depth m |

| Air BAR |

Liquid BAR |

A |

B |

C |

| cm |

cm |

cm |

| AF1010SS |

1.1 |

0.7 |

23 |

30 |

38 |

1.5 |

| 2.1 |

1.4 |

28 |

33 |

43 |

1.8 |

| 2.8 |

2.1 |

30 |

36 |

51 |

1.8 |

| 3.4 |

2.8 |

36 |

41 |

56 |

2.1 |

| 5.9 |

4.1 |

36 |

43 |

58 |

2.1 |

| AF1020SS |

1.1 |

0.7 |

28 |

36 |

48 |

1.5 |

| 2.1 |

1.4 |

36 |

43 |

53 |

1.8 |

| 2.9 |

2.1 |

36 |

46 |

58 |

1.8 |

| 3.4 |

2.8 |

41 |

48 |

66 |

2.1 |

| 5.5 |

4.1 |

41 |

53 |

74 |

2.4 |

| AF1030SS |

1.4 |

0.7 |

28 |

36 |

48 |

3 |

| 2.2 |

1.4 |

38 |

43 |

58 |

3.4 |

| 2.9 |

2.1 |

41 |

53 |

74 |

3.7 |

| 3.7 |

2.8 |

48 |

64 |

84 |

4.3 |

| 5.2 |

4.1 |

51 |

66 |

89 |

4.6 |

| AF1040SS |

1.1 |

0.7 |

36 |

46 |

61 |

3 |

| 2.2 |

1.4 |

38 |

48 |

69 |

3.7 |

| 3.2 |

2.1 |

43 |

58 |

76 |

4 |

| 3.9 |

2.8 |

51 |

64 |

86 |

4.6 |

| 5.9 |

4.1 |

53 |

69 |

91 |

4.6 |

| AF1050SS |

1 |

0.7 |

36 |

46 |

58 |

3 |

| 1.8 |

1.4 |

38 |

48 |

61 |

4 |

| 2.6 |

2.1 |

41 |

51 |

64 |

4.9 |

| 3.3 |

2.8 |

43 |

51 |

69 |

5.5 |

| 4.8 |

4.1 |

43 |

53 |

74 |

5.8 |

Air and Liquid Volume

air pressure/ inlet pressure, l/h = liter per hour atomized liquid, l/min = standard liter per minute air consumption

|

0.7 BAR Liquid |

1.4 BAR Liquid |

2.1 BAR Liquid |

| Model |

Air Pressure BAR |

l/h |

l/min |

Air Pressure BAR |

l/h |

l/min |

Air Pressure BAR |

l/h |

l/min |

| AF1010SS |

0.7 |

6.1 |

20 |

1.2 |

7.9 |

28 |

1.9 |

9.1 |

40 |

| 1 |

5.3 |

25 |

1.8 |

6.4 |

37 |

2.8 |

6.8 |

51 |

| 1.2 |

4.2 |

31 |

2.3 |

4.5 |

48 |

3.3 |

5.3 |

59 |

| 1.5 |

3 |

37 |

2.8 |

3 |

54 |

3.8 |

3.8 |

68 |

| AF1020SS |

0.8 |

9.1 |

20 |

1.4 |

12.9 |

25 |

2.1 |

14.8 |

34 |

| 1.1 |

6.8 |

25 |

1.9 |

9.1 |

34 |

2.6 |

11 |

42 |

| 1.2 |

5.7 |

28 |

2.2 |

6.8 |

42 |

3.2 |

7.6 |

54 |

| 1.4 |

4.9 |

31 |

2.5 |

5.3 |

48 |

3.4 |

6.1 |

59 |

| AF1030SS |

1.1 |

17 |

57 |

1.9 |

22.7 |

79 |

2.6 |

26.5 |

99 |

| 1.4 |

12.5 |

68 |

2.2 |

18.9 |

88 |

2.9 |

24.2 |

108 |

| 1.7 |

9.1 |

76 |

2.3 |

17 |

93 |

3.2 |

20.8 |

116 |

| 1.9 |

5.7 |

88 |

2.5 |

14.8 |

99 |

3.3 |

19.3 |

125 |

| AF1040SS |

0.8 |

30.7 |

40 |

1.5 |

45.4 |

54 |

2.3 |

49.6 |

76 |

| 1.1 |

22.3 |

51 |

2.1 |

26.9 |

76 |

2.9 |

33.7 |

96 |

| 1.2 |

18.9 |

57 |

2.3 |

21.2 |

88 |

3.3 |

23.8 |

116 |

| 1.5 |

12.5 |

68 |

2.6 |

15.5 |

99 |

3.6 |

18.9 |

127 |

| AF1050SS |

1 |

33.3 |

85 |

1.8 |

43.5 |

122 |

2.3 |

78.7 |

130 |

| 1.1 |

20.1 |

105 |

1.9 |

29.5 |

139 |

2.5 |

64.3 |

139 |

| — |

— |

— |

— |

— |

— |

2.8 |

34.1 |

173 |

| — |

— |

— |

— |

— |

— |

2.9 |

23.8 |

198 |

air pressure/ inlet pressure, l/h = liter per hour atomized liquid, l/min = standard liter per minute air consumption

|

2.8 BAR Liquid |

4.1 BAR Liquid |

| Model |

Air Pressure BAR |

l/h |

l/min |

Air Pressure BAR |

l/h |

l/min |

| AF1010SS |

2.6 |

9.8 |

48 |

3.8 |

12.1 |

62 |

| 3.4 |

7.6 |

59 |

5.2 |

8.7 |

85 |

| 4.1 |

6.1 |

71 |

6.2 |

6.1 |

102 |

| 4.8 |

4.5 |

85 |

6.9 |

4.9 |

116 |

| AF1020SS |

2.6 |

17.4 |

40 |

4.5 |

17.8 |

62 |

| 3.4 |

12.1 |

54 |

5.2 |

14 |

74 |

| 4.1 |

8.3 |

65 |

5.9 |

10.6 |

85 |

| 4.8 |

5.3 |

79 |

6.6 |

7.9 |

102 |

| AF1030SS |

3.2 |

32.2 |

113 |

4.5 |

41.6 |

150 |

| 3.6 |

28.4 |

127 |

4.8 |

37.9 |

161 |

| 4 |

23.8 |

139 |

5.5 |

30.3 |

181 |

| 4.1 |

22.7 |

147 |

6.2 |

24.2 |

204 |

| AF1040SS |

3.2 |

54.1 |

96 |

4.5 |

69.3 |

127 |

| 3.7 |

39 |

116 |

5.5 |

45 |

167 |

| 4.1 |

29.9 |

136 |

6.2 |

32.2 |

193 |

| 4.8 |

17.4 |

164 |

6.9 |

22.7 |

224 |

| AF1050SS |

2.9 |

114 |

136 |

4 |

159 |

156 |

| 3.2 |

77.6 |

173 |

4.5 |

114 |

193 |

| 3.4 |

51.1 |

207 |

4.8 |

79.5 |

246 |

| 3.7 |

28.4 |

238 |

5.5 |

32.2 |

317 |