Silencing Mufflers

- Reduce work area noise

- Eliminates exhaust air oil mist

- High flow capacity

- Low back pressure

- Popular NPT sizes for easy retrofit for new and existing installations

- Prevents open dead end pressures

EXAIR Silencing Mufflers help to reduce work area noise produced by air exhausting from cylinders, valves and other air powered equipment. Per OSHA standard 1910.95, a worker must not be exposed to sound levels above 90 dBA for any eight hour shift of a 40 hour work week. Silencing Mufflers help plants meet this OSHA requirement by reducing the sound to safe levels below 90 dBA. They also eliminate harmful dead ended pressures. Each style of Silencing Muffler shown has a high airflow capacity, with low back pressure. Popular NPT sizes are ideal for new and existing installations.

Sintered Bronze Mufflers

| Model | UOM | Overall Length A | Hex B | Thread Size C |

|---|---|---|---|---|

| 9080 | in | 0.72 | 0.31 | #10-32 |

| mm | 18 | 8 | ||

| 9081 | in | 1.13 | 0.44 | 1/8 NPT |

| mm | 29 | 11 | ||

| 9082 | in | 1.38 | 0.56 | 1/4 NPT |

| mm | 35 | 14 | ||

| 9083 | in | 1.50 | 0.69 | 3/8 NPT |

| mm | 38 | 18 | ||

| 9084 | in | 1.88 | 0.88 | 1/2 NPT |

| mm | 48 | 22 | ||

| 9085 | in | 2.25 | 1.06 | 3/4 NPT |

| mm | 57 | 27 | ||

| 9086 | in | 2.91 | 74 | 1 NPT |

| mm | 1.31 | 33 | ||

| 9087 | in | 3.25 | 83 | 1 – 1/4 NPT |

| mm | 43 | 2 | ||

| 9088 | in | 3.69 | 94 | 1 -1/2 NPT |

| mm | 2 | 51 | ||

| *9089 | in | 1.19 | 30 | 1/2″ – 20 Female |

| mm | 0.63 | 16 |

*Model 9089 for solenoid valves only

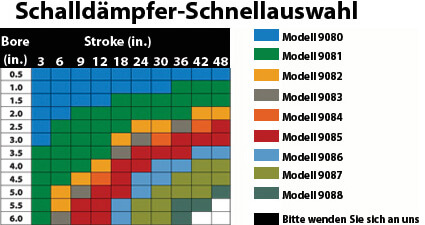

Muffler will exhaust cylinder in 1/2 second for a cylinder charged to 100 PSIG.

Reclassifying Mufflers

Reclassifying Mufflers are an upgrade from Sintered Bronze Mufflers. They offer the best noise reduction – up to 35 dB. Reclassifying Mufflers eliminate oil mist. Exhaust air from cylinders and valves often contain oil mists that can contaminate the workers’ breathing air, affecting their health. Per OSHA standard 29 CFR 1910.10, a worker’s cumulative exposure to oil mist must not exceed 4.32 PPM (particles per million) in any eight hour shift of a 40 hour work week.

The patented wrap design of the removable element separates oil from the exhausted air so virtually no oil is released into the environment. Based on the intake of 50 PPM at 100 PSIG, the Reclassifying Mufflers reclassify and reduce the exhausted oil mist to .015 PPM. A reservoir where oil accumulates at the bottom can be drained by attaching a 1/4″ tube.

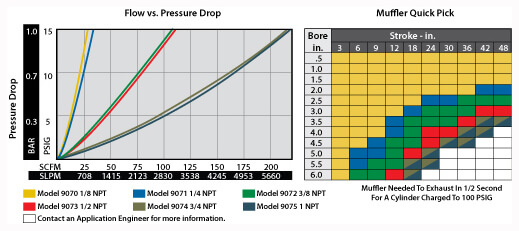

Each Reclassifying Muffler passes a certain volume of air with minimal back pressure restriction so it doesn’t interfere with the operation of the cylinder or valve. When used with cylinders, the “Muffler Quick Pick” table helps you select the appropriate model based on the actual bore and stroke of the cylinder.

Two tools are provided below to help you choose the model best suited to your application. The “Flow vs. Pressure Drop” performance curves show the amount of back pressure that builds as flow through the muffler is increased. For cylinders, use the “Muffler Quick Pick” table that helps you select a model that provides minimum back pressure restriction based on the actual bore and stroke of your cylinder (based on an acceptable exhaust time of 0.5 seconds).

| Modell | Description | UOM | Overall Length | Width | NPT | Replacement Element # |

|---|---|---|---|---|---|---|

| 9070 | Reclassifying Muffler | in | 3.13 | 1.63 | 1/8 NPT | 900553 |

| mm | 80 | 41 | ||||

| 9071 | Reclassifying Muffler | in | 3.13 | 1.63 | 1/4 NPT | |

| mm | 80 | 41 | ||||

| 9072 | Reclassifying Muffler | in | 4.75 | 2.44 | 3/8 NPT | 900554 |

| mm | 121 | 62 | ||||

| 9073 | Reclassifying Muffler | in | 4.75 | 2.44 | 1/2 NPT | |

| mm | 121 | 62 | ||||

| 9074 | Reclassifying Muffler | in | 6.25 | 3.31 | 3/4 NPT | 900555 |

| mm | 159 | 84 | ||||

| 9075 | Reclassifying Muffler | in | 6.25 | 3.31 | 1 NPT | |

| mm | 159 | 84 |

Straight-Through Mufflers

Straight-Through Silencing Mufflers feature a corrosion-resistant aluminum outer shell lined with sound-absorbing foam for better noise reduction. The typical noise reduction is up to 20 dB.

| Model | Description | UOM | A | B | C | D | E | Rated Flow |

|---|---|---|---|---|---|---|---|---|

| 3905 | Straight-Through Muffler | in | 4 | 1.5 | .5 | 1/4 NPT (Male) | 1/4 NPT (Female) | 22 SCFM |

| mm | 102 | 38 | 13 | 623 SLPM | ||||

| 3911 | Straight-Through Muffler | in | 4.13 | 1.5 | .63 | 3/8 NPT (Male) | 3/8 NPT (Female) | 50 SCFM |

| mm | 105 | 38 | 16 | 1415 SLPM | ||||

| 3913 | Straight-Through Muffler | in | 9.75 | 2 | .75 | 3/4 NPT (Male) | 3/4 NPT (Female) | 73 SCFM |

| mm | 248 | 51 | 19 | 2066 SLPM |

Caution: Operations approaching 32°F (0°C) could result in freeze-up due to moisture in the compressed air line.

Heavy Duty Mufflers

Heavy Duty Silencing Mufflers feature a corrosion-resistant aluminum outer shell with an internal stainless steel screen that protects valves and cylinders from contamination that could enter through the exhaust ports. This also keeps contaminants such as rust from being ejected at high speed from the exhaust port. The typical noise reduction is up to 14 dB.

| Model | Description | UOM | A | B | C | D | E |

|---|---|---|---|---|---|---|---|

| 3903 | Heavy Duty Muffler | in | 1.81 | 0.81 | .44 | 63 | 1/4 NPT (Female) |

| mm | 46 | 21 | 11 | 16 | |||

| 3907 | Heavy Duty Muffler | in | 4.5 | 2 | .75 | 1.5 | 3/4 NPT (Female) |

| mm | 114 | 51 | 19 | 38 |