Here you can read the current article about the GrindTec Augsburg International Trade Fair from March 14-17,2018 in Hall 9, Booth 7

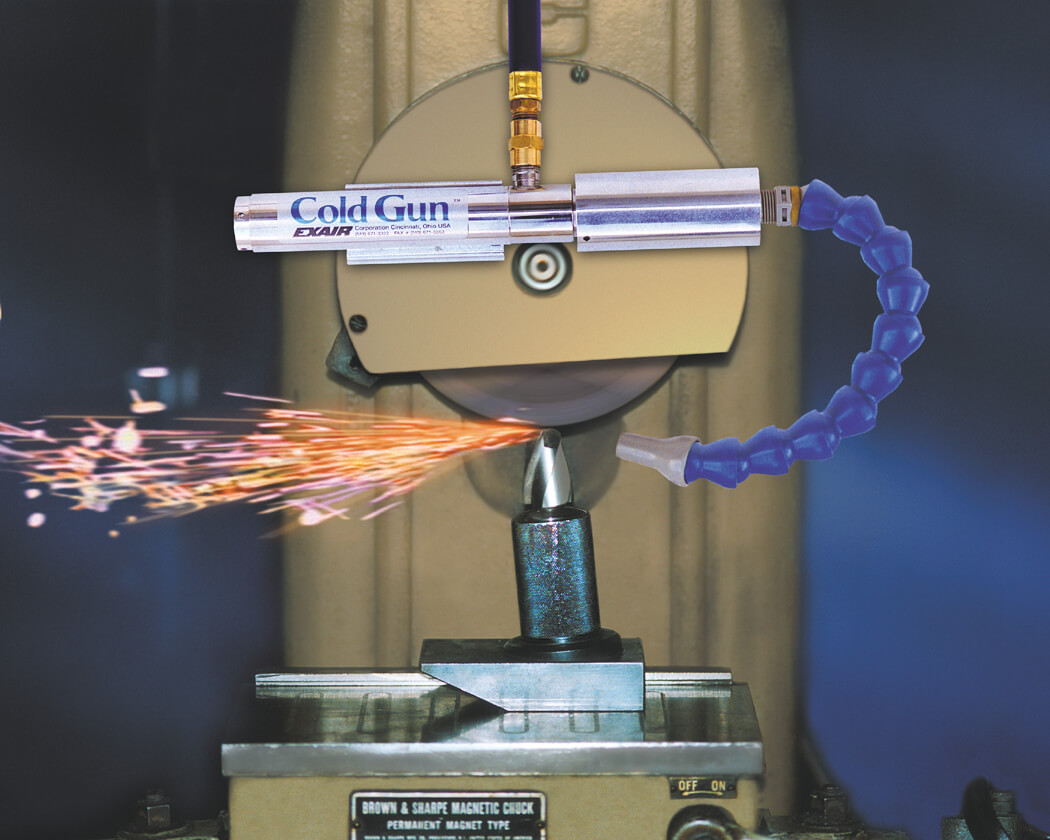

It is well known that the heat build up on dry machining operations reduces tool life and machining rates. The Cold Gun Aircoolant System, from Exair Corp., whose exclusive distributor is Eputec Drucklufttechnik for the DACH region, offers the possibility of concentrate and local cooling. The Cold Gun produces a stream of clean, cold air at 28 degrees Celsius below the supply air temperature.

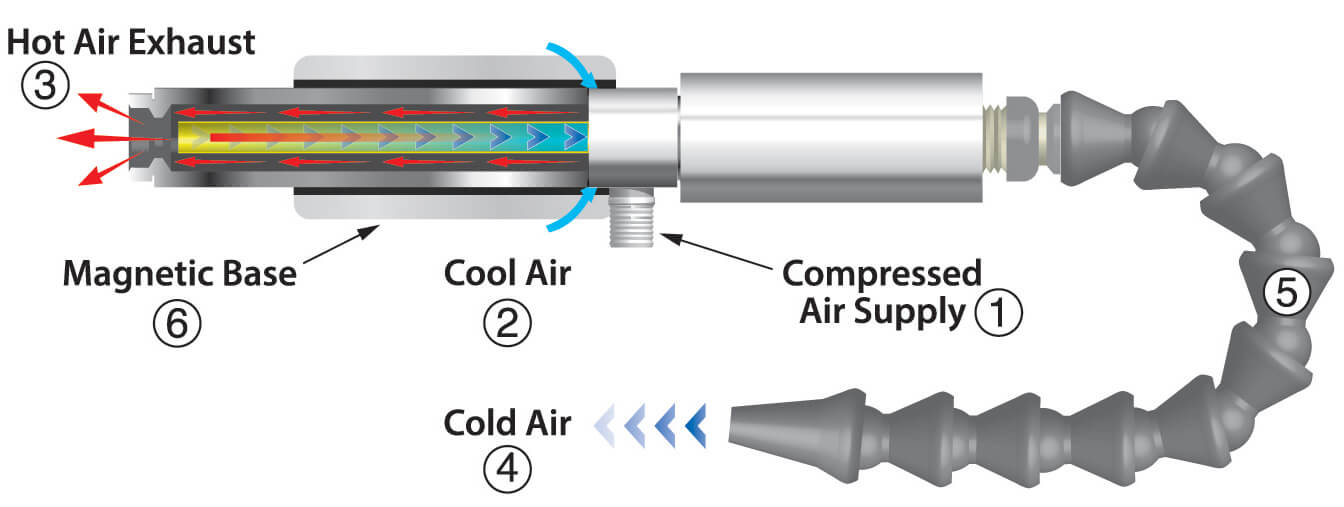

The Cold Gun incorporate a vortex tube to convert an ordinary supply of compressed air into two low pressure streams, one hot and one cold. The Cold Gun´s hot airstream is muffled and discharged through th hot air exhaust. The cold air is muffled and discharged through the flexible hose, which directs it to the point of use. The easy mounting and portability are provided through the use of an attached magnetic base.

The cold air guns are not adjustable to prevent freezing during use. To optimize the cooling capacity of the gun, the cold air flow and temperature drop are factory set.

The advantages of the Cold Gun compared to a conventional coolant system are obvious:

• Improvement of production rates

• Prevents smearing of metals and plastics

• Finished part is dry

• Quiet (only 70 dBA)

• No coolant cost

• Improvement of tolerance control

• Low cost – no electricity

• Extends tool life – reduces breakage

All this with an air consumption of 425 SLPM (standard cold air pistol) or 850 SLPM (high performance cold air pistol) at 6.9 bar.

Experience shows that cooling lubricants can be dispensed with in many grinding processes and concentrate cooling is an effective alternative. The Cold Gun can be seen live at this year’s GrindTec in Augsburg, Hall 9, Booth 9106 at Eputec Drucklufttechnik GmbH.