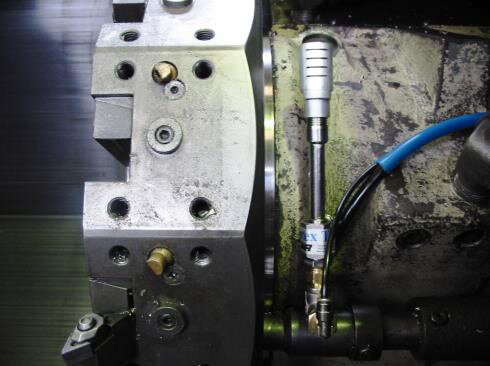

AIR LUBROCOLD – Minimal lubrication and cooling system for machine tools and industrial applications. It provides a continuous cold air flow adding lubricant micro injections at the same time.

Air-oil lubrication is a recent technology compared to the other machine tools cooling systems. It was especially developed to comply with most recent high performance machines and tools, granting in the mean time low environmental impact and coolant cost reduction. Air Lubrocold system is gradually replacing the traditional spraying systems who have a huge impact on environment conditions.

What is AIR LUBROCOLD?

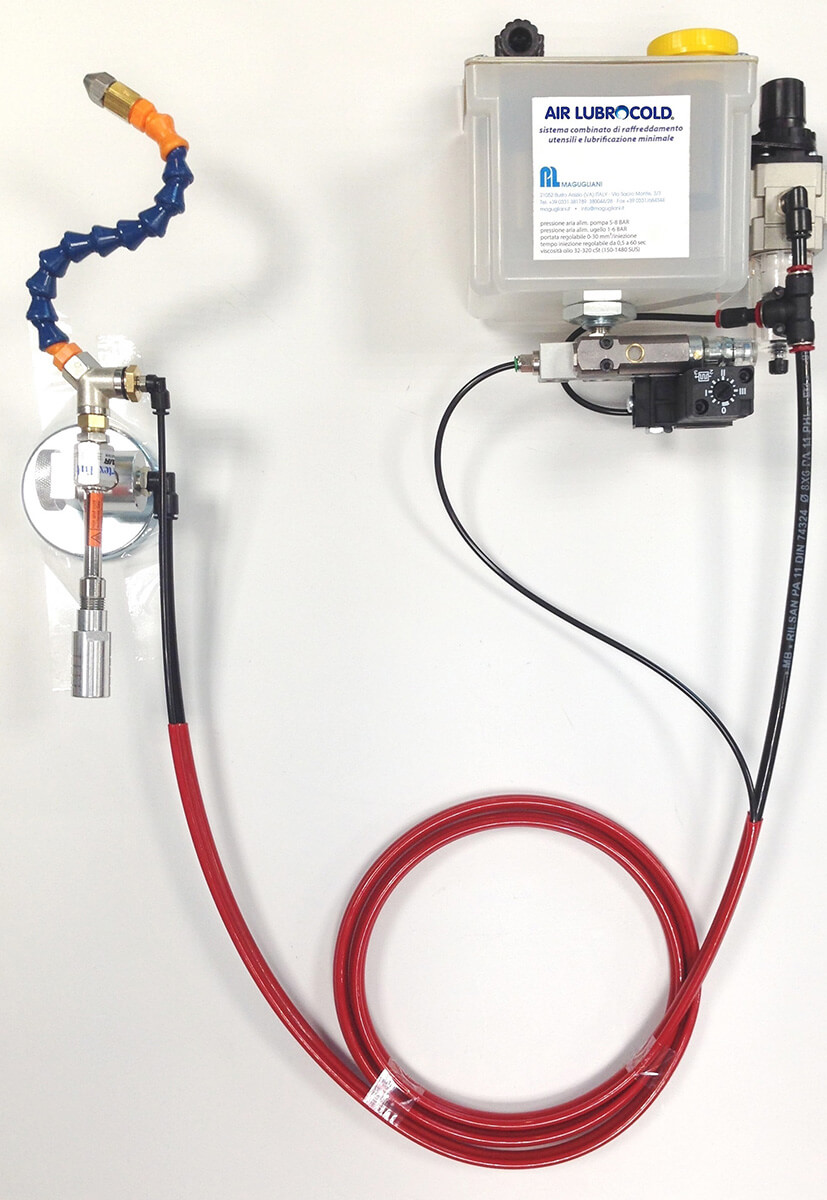

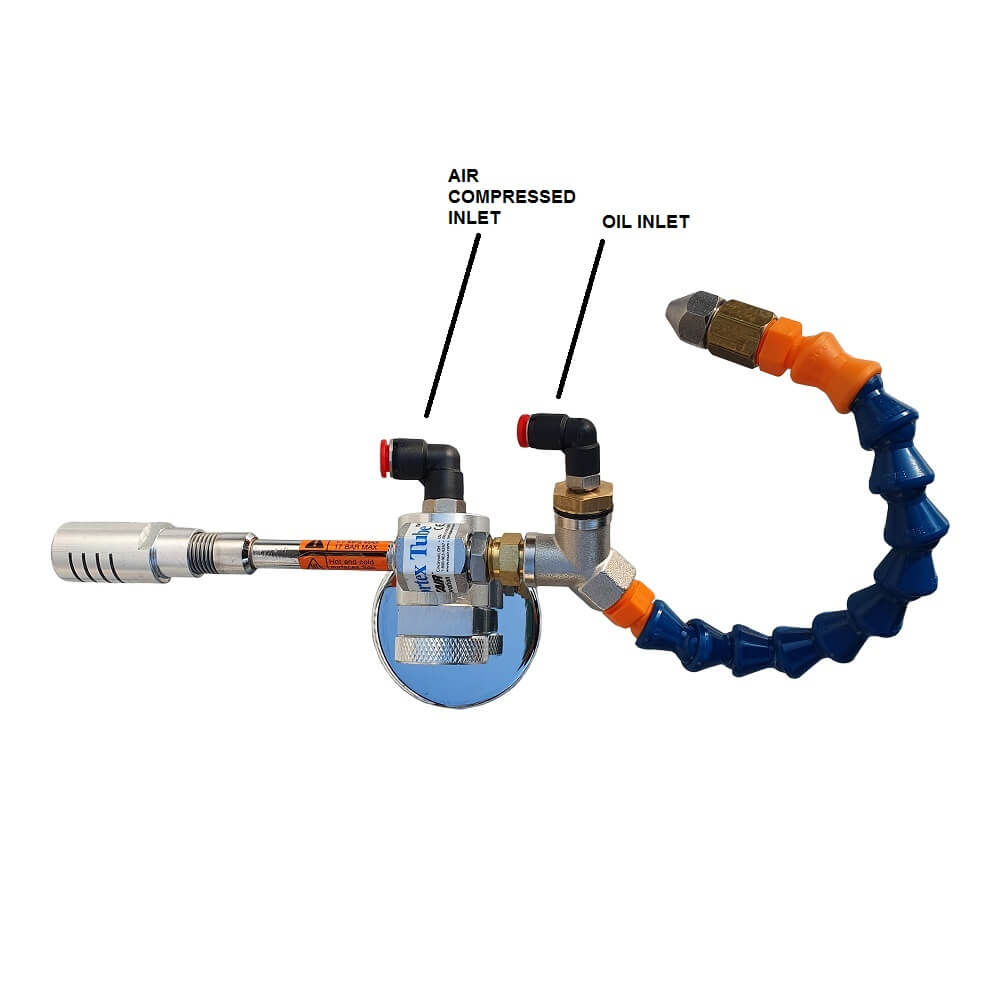

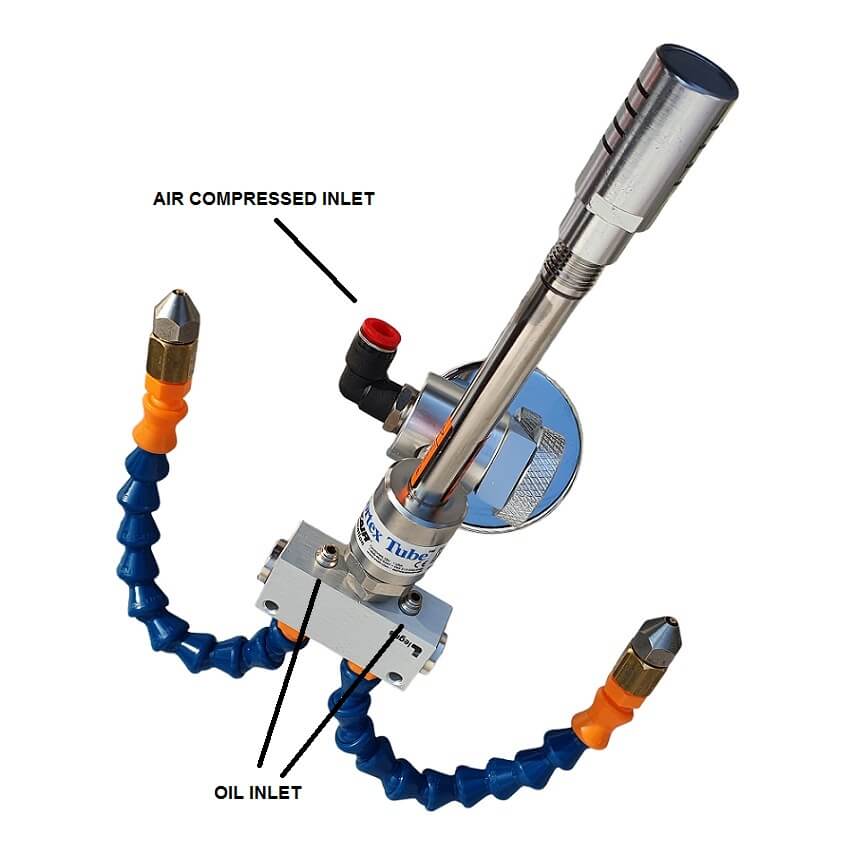

It is a device composed by two main components working in combination, an Exair vortex tube used to generate a cold air flow and a small piston pump used to provide cyclic oil micro injections. AIR LUBROCOLD works with compressed air, it can be operated by a pneumatic timing element or by a solenoid valve directly connected with the CNC system.

How it works

AIR LUBROCOLD provides a continuous cold air flow (adjustable temperature) enriched by cyclic oil micro injections (adjustable cycle and oil quantity) granting both cooling and tools lubrication.

Available versions

AIR LUBROCOLD it available with the following main versions:

- Single output with flexible hose, suitable for milling, lathe, drilling, tapping

- Single output with fork type nozzle, suitable for saw mills and cutters

- Double output for heavy duty applications where a superior cooling capacity is required or where the tools need to be lubricated on both sides

- All versions are available with open version or fully enclosed in a steel box

| Article Number | Description (open version) |

| 4016505 | Cooling – minimal lubrication system 1 lt. tank, single output single pump with timer |

| 4016506 | Cooling – minimal lubrication system 1 lt. tank, single output (fork type for band saw machines and cutters) single pump with timer |

| 4016502 | Cooling – minimal lubrication system 3 lt. tank, single output single pump with timer |

| 4016507 | Cooling – minimal lubrication system 3 lt. tank, single output (fork type for band saw machines and cutters) single pump with timer |

| 4016503 | Cooling – minimal lubrication system 1 lt. tank, single output single pump without timer |

| 4016504 | Cooling – minimal lubrication system 3 lt. tank, single output single pump without timer |

| 4016510 | Cooling – minimal lubrication system 1 lt. tank double outputs double pump with timer |

| 4016501 | Cooling – minimal lubrication system 3 lt. tank double outputs double pump with timer |

| 4016508 | Cooling – minimal lubrication system 1 lt. tank double outputs double pump without timer |

| 4016509 | Cooling – minimal lubrication system 3 lt. tank double outputs double pump without timer |

| Article Number | Description (fully enclosed version) |

| 4016516 | Fully enclosed cooling – minimal lubrication system 1,2lt. tank, single output single pump with timer |

| 4016517 | Fully enclosed cooling – minimal lubrication system 1,2 lt. tank, single output (fork type for band saw machines and cutters) single pump with timer |

| 4016515 | Fully enclosed cooling – minimal lubrication system 2,2lt. tank, single output single pump with timer |

| 4016522 | Fully enclosed cooling – minimal lubrication system 2,2 lt. tank, single output (fork type for band saw machines and cutters) single pump with timer |

| 4016514 | Fully enclosed cooling – minimal lubrication system 1,2lt. tank, single output single pump without timer |

| 4016513 | Fully enclosed cooling – minimal lubrication system 2,2lt. tank, single output single pump without timer |

| 4016521 | Fully enclosed cooling – minimal lubrication system 1,2lt. tank, double outputs double pumps with timer |

| 4016520 | Fully enclosed cooling – minimal lubrication system 2,2lt. tank, double outputs double pumps with timer |

| 4016519 | Fully enclosed cooling – minimal lubrication system 1,2lt. tank, double outputs double pumps without timer |

| 4016518 | Fully enclosed cooling – minimal lubrication system 2,2lt. tank, double outputs double pumps without timer |

| Article Number | Conversion Kit |

| 4016511 | Conversion kit from minimal lubrication system to cold – minimal lubrication system single output |

| 4016512 | Conversion kit from minimal lubrication system to cold – minimal lubrication system double output |