Line Vac™ – Convey parts, materials, waste – with no moving parts!

It is a fast, low cost way to convey:

- Plastic pellets

- Scrap trim

- Textiles

- Bulk solids

- Food products

- Chips

- Paper

- Pills/tablets

- Small parts

- Shavings

- Sawdust

- Granules

What Is The Line Vac?

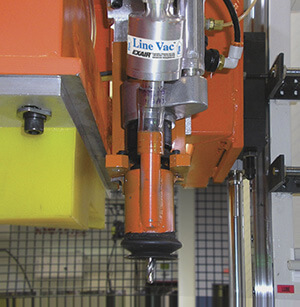

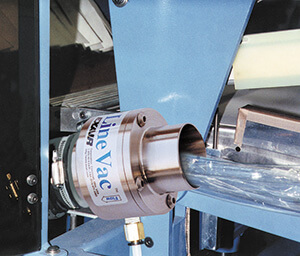

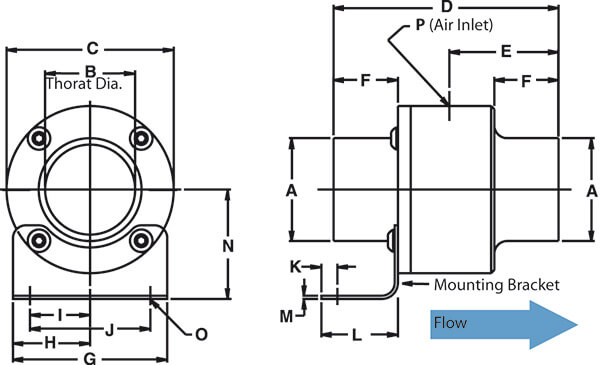

EXAIR’s compressed air operated Line Vac connects to standard hose or tube to create a powerful in-line conveyor. The compact design features large throat diameters for maximum throughput capacity. Eleven sizes in aluminum and ten sizes in stainless steel are suited to a wide variety of transfer applications.

Why The Line Vac?

These conveyors are ideal for moving large volumes of material over long distances. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other, with instantaneous response. The material flow rate is easily controlled with a pressure regulator. An optional bracket permits easy mounting. No moving parts or electricity assures maintenance-free operation.

On our overview page you will find different vacuum conveyor variants that can be used for pneumatic conveying.

The table below gives a quick comparison of our Light Duty Line Vac, standard Line Vac and the Heavy Duty Line Vac. For comparison, the test shows the 2″ (51mm) model of each style conveying the same material over various lengths.

| Rock Salt Conveying Rate Comparison | ||

|---|---|---|

| 100 Feet (30,5 m) | 200 Feet (61 m) | |

| Light Duty Line Vac (Model 130200 2″ (51mm)) | 166 lbs/hr. (75,3 kg/Std.) | N/A |

| Line Vac (Model 6084 2″ (51 mm)) | 334 lbs/hr. (151,5 kg/Std.) | 85 lbs/hr. (38,6 kg/Std.) |

| Heavy Duty Line Vac (Model 150200 2″ (51mm)) | 524 lbs/hr. (237,7 kg/Std.) | 200 lbs/hr. (90,7 kg/Std.) |