Air Amplifier (venturi nozzle)

Our Air Amplifiers are quiet and at the same time very efficient. They amplify the air volume up to 25 times the compressed air consumption!

What are Air Amplifiers (Venturi Nozzles or Airflow Amplifiers)?

Venturi nozzles are a simple and cost-effective way of transporting or moving air, smoke, gases and lightweight materials. In addition, these air amplifiers are an optimal solution for cooling large components or for drying workpieces.

All Air Amplifiers use the Coanda effect, a basic fluidic operating principle. The air amplifiers have low compressed air consumption, but entrain a lot of ambient air. As a result, they create a large volume of air at high velocity when the air exits.

For example, our Adjustable Air Amplifiers are suitable for cooling and drying large metal parts in a foundry (as seen in the picture).

Why use air amplifiers (venturi tubes)?

Air amplifiers have no moving parts and are maintenance free. An electrical connection is not needed.

Additionally, the flow rate, vacuum and speed are easy to control. The flow rate at the air exit can be easily increased by enlarging the opening gap. Similarly, the flow rate at the air exit can be easily decreased by reducing the input pressure. The two sides, the air intake or air discharge end of the air amplifier can be connected using hoses; they are ideally suited to, e.g., taking in fresh air from a different zone, or from the ambient air, or extracting smoke and gases.

In this application, several Adjustable Air Amplifiers are joined by piping to take in clean air for drying.

A model 120024 4″ (102 mm) Super Air Amplifier cooling an engine on a torque test bed.

Examples of the use of air amplifiers

- Extracting welding fumes

- Cooling hot products and materials

- Drying wet objects

- Cleaning machined workpieces

- Heat distribution in casting or furnaces

- Ventilating delimited areas

- Extracting tank gases

- Blowing off

- Cooling

Benefits compared to fans:

- Compact

- Lightweight

- Portable

- No electricity needed

- Variable in terms of force and flow

- Face sides can easily be fitted with baffles

- No moving parts – no maintenance

- Immediately on or off

- Benefits compared to ejectors:

- More powerful air flow despite lower compressed air consumption

- Quiet

- No obstructions on the inside and no moving parts

- Compliant with OSHA pressure and noise requirements

Benefits compared to ejectors:

- Stronger air flow with lower compressed air consumption

- Quiet

- No internal obstructions and no moving parts

- Meets OSHA pressure and noise requirements

How do air amplifiers work?

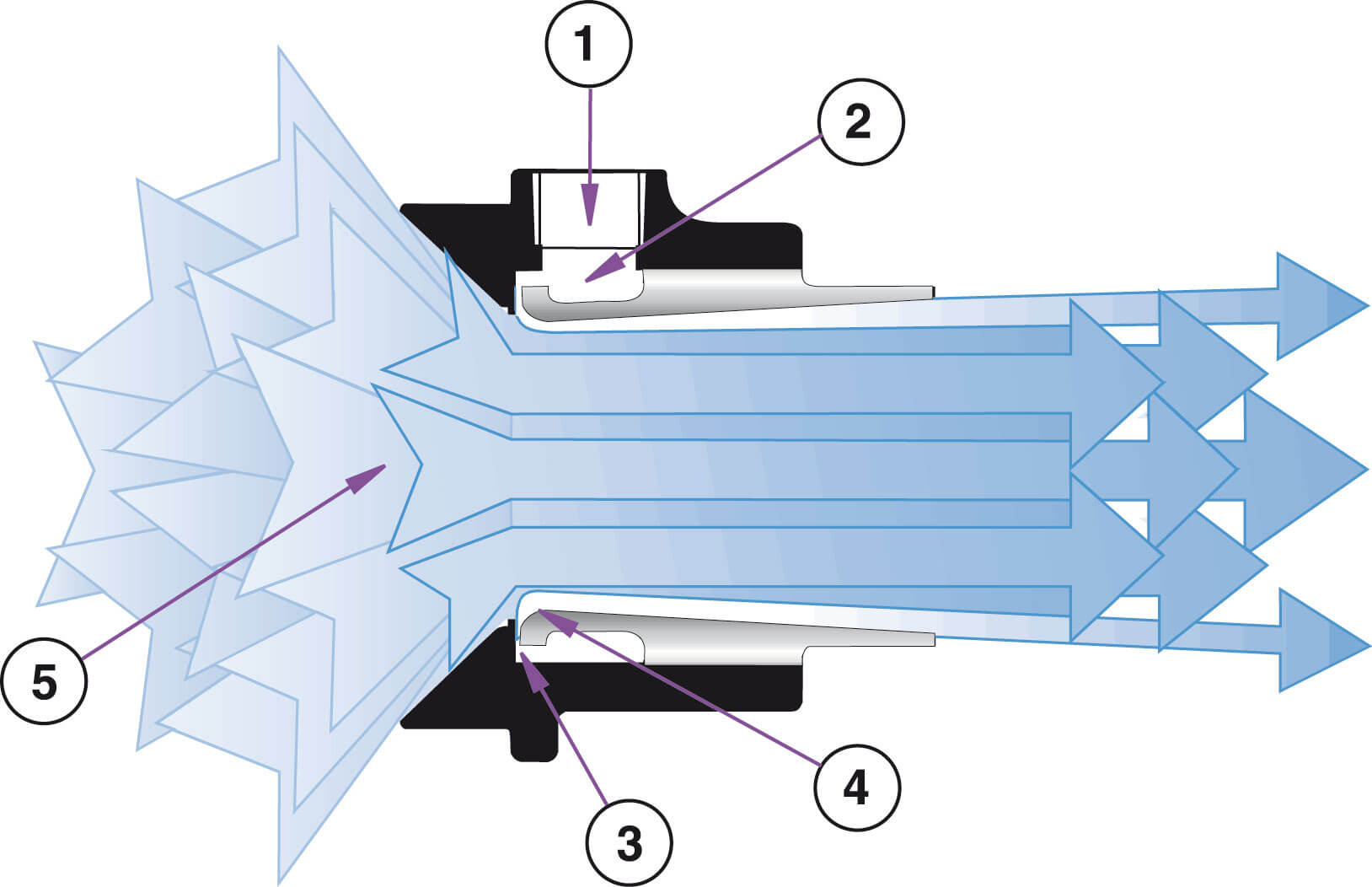

Compressed air flows through a feed (1) into an annular chamber (2).

The air is then pressured through a small annular nozzle (3) at high speed. This primary air flow follows the Coandă profile (4) and is routed directly through the discharge aperture.

This generates an area of negative pressure at the centre (5) which causes a high volume of ambient air to be fed into the primary air flow.

The result: The combined primary and ambient air flow exits the air amplifier with a high air volume and high flow speed.

Which Air Amplifier fits my needs?

- Super Air Amplifiers (super venturis) offer the best air flow amplification and are the most efficient amplifiers in the Air Amplifier series.

- Adjustable Air Amplifiers (adjustable venturis) offer a good amplification factor and are very easy to handle.

| Air Amplifiers compared | ||||||

|---|---|---|---|---|---|---|

| capacity | noise level | fastening flange | flow adjustment | as-designed temperature range | corrosive applications | |

| Super Air Amplifier | high | low | yes | with spacer films | 135 °C (275 °F) | no |

| Aluminium Adjustable Air Amplifier | medium | variable | no | continuous (no spacer films) | 135 °C (275 °F) | no |

| Stainless-Steel Adjustable Air Amplifier | mediuml | variable | no | continuous (no spacer films) | 204 °C (400 °F) | yes |

| High temperature Air Amplifier | high | low | no | with spacer films | 374 °C (700 °F) | yes |